Co u nás právě letí?

Na základě dohody s programem Clean Aviation Evropské komise získá konsorcium vedené společností Avio Aero přibližně 34 milionů eur (827 milionů Kč) na vývoj předváděcího programu...

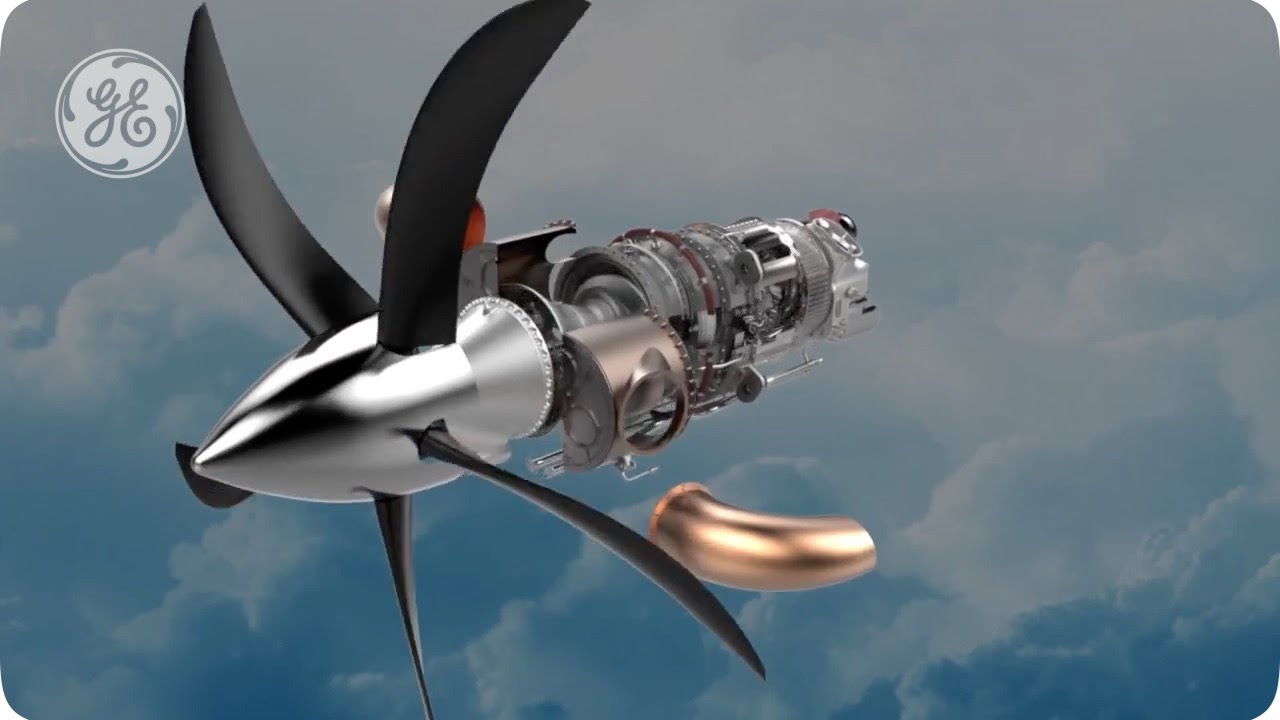

Pokročilý evropský turbovrtulový motor byl vybrán divizí společnosti Airbus zodpovědnou za vývoj obranných a leteckých produktů a služeb pro nový letoun Eurodrone

Oznámení přichází v den 5. výročí partnerství veřejného a soukromého sektoru rozšiřujícího spolupráci ve výzkumu a vývoji leteckých technologií